Manufacturing Limits

Manufacturing limits represent all non-statistical limits. Typically, you define these requirements before the first piece rolls off of the production line, giving you a clear understanding of the requirements before production starts. You do not need to collect any production data prior to defining the requirements. When creating manufacturing limits, you must select a specific part and a specific feature. During creation, you may also select a process, though Enact will apply the configured manufacturing limits to the selected process and also all processes and subprocesses below it in the hierarchy.

Manufacturing limits with selected processes will always override manufacturing limits without selected processes.

Manufacturing limits include the following:

-

Specification Limits. Based on either external requirements (customer, engineering, or management) or on internal requirements (subsequent processes), specification limits identify the tolerances or engineering limits for a part and test combination to determine product acceptability. You must define specification limits before you can define certain statistics, such as Cpk and Ppk.

- Warning Limits. Set within the specification limits, you can use warning limits to notify users that a measurement value is close to an upper or lower specification limit.

- Reasonable Limits. Typically set well beyond specification limits, you can use reasonable limits to identify (or prevent) data entry errors, such as transposed numbers, since Enact ignores values beyond the reasonable limits in calculations.

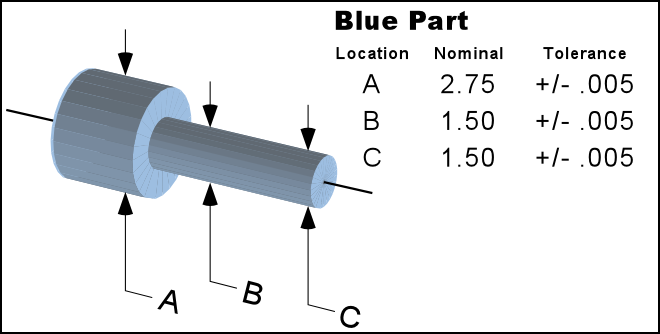

- Within Piece Limits. Used exclusively for sub-tests, within-piece limits identify the tolerances or engineering limits for multiple measurements taken for the same test but at different locations. For example, you can verify the roundness of a drilled hole by measuring the diameter of the hole in three indexed locations, and comparing the average of the within-piece values against the within-piece limits.

- Subgroup Limits. Subgroup limits are used to test the plot point against a specification limit. When collecting attribute data, you must use subgroup limits, where the plot point represents a total sample defect count. When collecting variable data, you can use subgroup limits, which are defined for the average of several measurements.

- MAV Method. The Maximum Allowable Variation Method is the tolerance below or above the stated content within which the US government permits a limited number of packs to be included in the lot. By default, Enact uses the same units for the MAV method as it does for the specification limits.

- T1T2 Method. The T1 and T2 set points are dividing lines between two weight zones. T1 Upper requires weight above the stated content allowed by the European Union and the average of the batch must exceed the Stated Content. T2 Upper data field requires weight above the stated content allowed by the European Union which must be above T1 and does not exceed 2.5% of the batch.